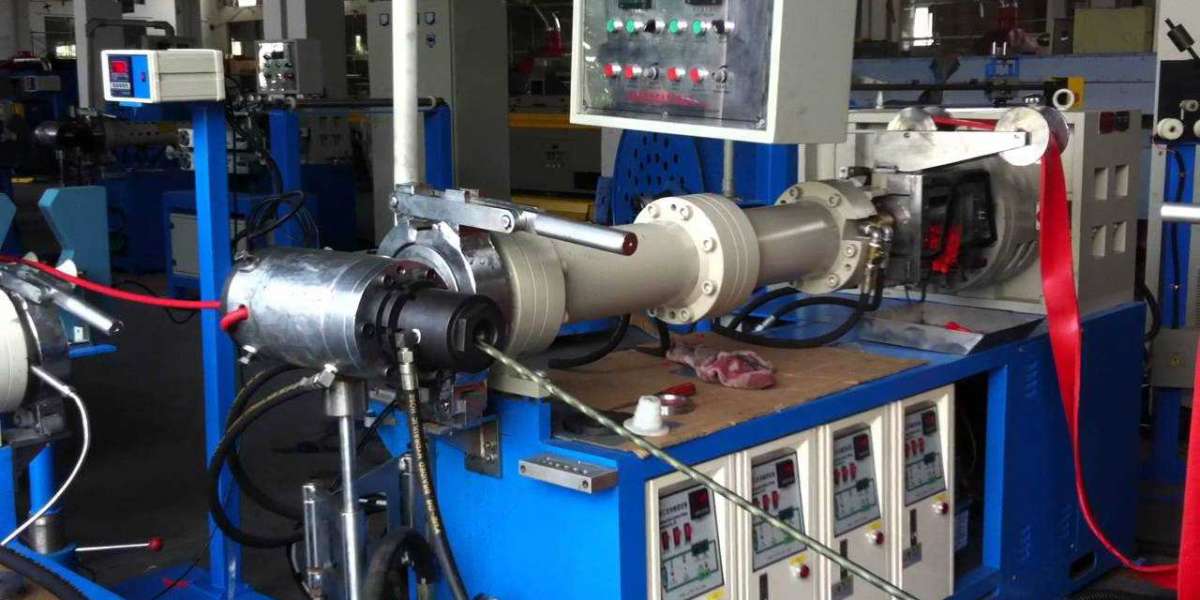

The rubber vulcanizing machine is suitable for the vulcanization and pressing of various rubber and plastic products; the preheating required for the rubber vulcanization process, the automatic exhaust gas after loading, the pressure maintaining vulcanization, the timer alarm, the automatic mold opening, and the product ejection are all integrated. Generally adopts PLC control, with automatic and manual operation (customized according to the actual needs of users), which can record the required process flow, remote operation and system management.

There are three common faults in the vulcanizing machine:

(1) Shaft wear

Because the vulcanizing machine is made of metal and has high hardness, it is subject to vibration and other combined forces during the production and operation process, which causes the parts to form gaps and cause wear. Traditional repair methods include surfacing, thermal spraying, brushing, etc., but several methods have certain disadvantages: surfacing will cause the surface of the part to reach a high temperature, causing the part to deform or crack, affecting dimensional accuracy and normal use. It will also cause fracture when it is serious; although the brush ferry has no thermal influence, the thickness of the ferry layer cannot be too thick, the pollution is serious, and the application is also greatly restricted. Western countries often use polymer composite methods to address these issues. It has comprehensive performance and can be machined at any time, which can meet the use requirements and accuracy after repair, and can also reduce the shock and vibration experienced by the equipment during operation and prolong its service life. Because the material is a "variable" relationship, when an external force strikes the material, the material will deform and absorb the external force, and expand and contract with the expansion or contraction of the bearing or other components, always maintaining a tight fit with the components, reducing the probability of wear. For the wear and tear of large-scale vulcanizing machines, "molds" or "matching components" can also be used to repair the damaged equipment on site, avoiding the overall disassembly of the equipment, maximizing the size of the components, and meeting the production and operation requirements of the equipment.

(2) Weld leak

During the long-term operation of the vulcanizing machine, due to the effects of vibration, wear, pressure, temperature, and repeated disassembly, oil leakage at the static sealing parts of the joint surfaces is very common, and the common is the leakage of the hot plate weld of the vulcanizing machine. Not only cause a lot of waste of oil products, but also affect the on-site management of the enterprise. Treatment method: After dismantling and opening the vulcanizer, replace the gasket or apply sealant.

(3) floor corrosion

The bottom plate of the vulcanizing machine is mostly ordinary carbon steel, and the tire is vulcanized by high temperature steam. During the process, part of the water condensed penetrates the surface of the bottom plate, causing the surface of the bottom plate to corrode unevenly. Due to the serious corrosion of the bottom plate surface, it cannot be closely matched with the surface of the heat insulation plate, and the heat insulation plate is easily damaged under a large pressure. Traditional methods are mainly based on re-machining after multiple surfacing or replacement of new equipment. At present, polymer composite materials can be used for on-site repair. Because the material has excellent adhesion, good corrosion resistance, and good compressive strength, it can effectively solve the unevenness caused by the condensed water on the bottom plate of the vulcanizer during operation, thereby avoiding the damage of the heat insulation plate and providing user equipment. Normal operation and safe production provide a good guarantee.

In the chemical industry, there are a lot of energy-using and electricity-consuming equipment. While maintaining the equipment well, it is also possible to continuously explore energy-saving methods for the equipment. The intelligent power-saving technology independently developed by Zhongke Yujie is widely used in steel, chemical industry, coal mines, commercial buildings, unit engineering projects and other fields. The eight smart equipment power-saving systems effectively solve serious energy consumption problems for industrial enterprises.