The base material of Stainless Steel Composite Panel can be used for all kinds of ordinary carbon steel and special steel. Materials and thicknesses can be freely combined to meet the needs of different users. Stainless steel composite panel is widely used in petroleum, chemical industry, salt industry, water conservancy and other industries. As a resource-saving product, stainless steel composite panel reduces the consumption of precious metals and greatly reduces the project cost. Achieving the perfect combination of low cost and high performance has good social benefits.

Stainless steel composite panel is a kind of pure stainless steel with outer shell, carbon steel as inner metal composite material, stainless steel/carbon steel composite material as stainless steel composite material, which is used to provide material guarantee for coking equipment manufacturing and upgrading.

Using stainless steel composite panel instead of original stainless steel plate can reduce the cost of equipment without affecting the use of equipment. Stainless steel composite panel can be used in desulfurization tower, steam ammonia tower, benzene removal, etc., with low cost and corrosion resistance; For example, using stainless steel composite panel instead of pure stainless steel plate can reduce the cost by more than 30%.

Secondly, keep the corrosion-resistant stainless steel plate of pure stainless steel, wear resistance, magnetic resistance and appearance characteristics, and have the characteristics of carbon steel and good weldability, formability, stretchability and thermal conductivity. It can be widely used in coking equipment, improving the corrosion resistance of coking equipment and prolonging the service life of equipment.

Stainless steel composite panel has good thermal conductivity and corrosion resistance, and can be used in coking equipment. If it is used in the steam ammonia tower, it can improve the service life of the steam ammonia tower and reduce the operation cost. On the other hand, it can be used in ammonia plant because of its corrosion resistance.

In short, manufacturing stainless steel composite panel in coking equipment, upgrading, is to improve the service life of the equipment, improve the production efficiency of the equipment, and reduce the operating cost.

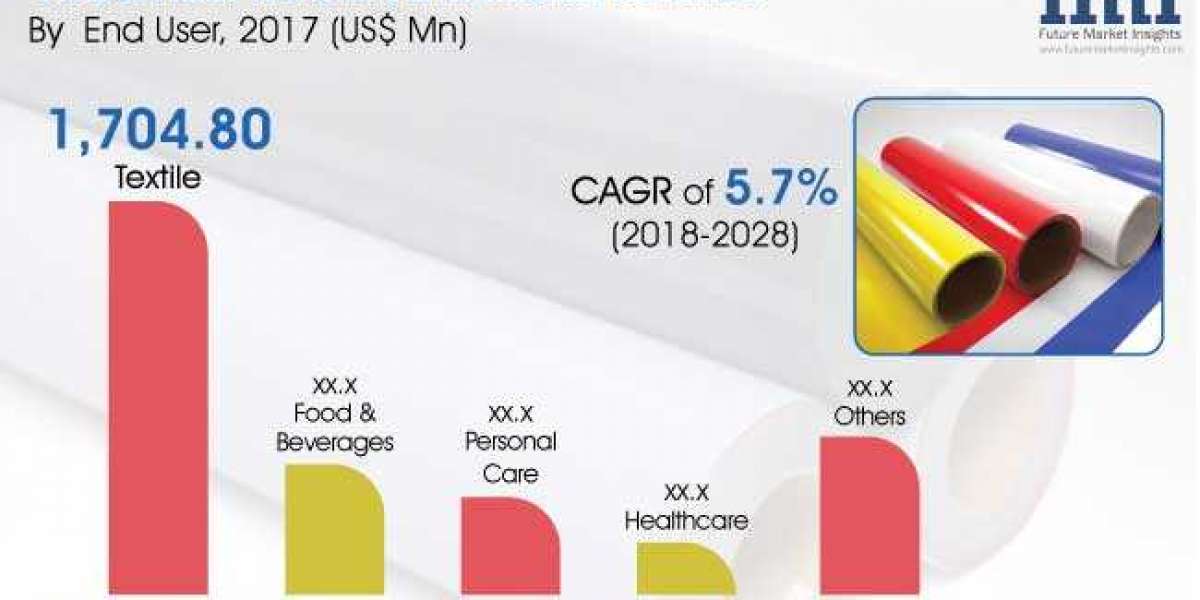

We are also a professional Aluminum Composite Panel Manufacturers, if necessary, please click our website: https://www.alubang.net/