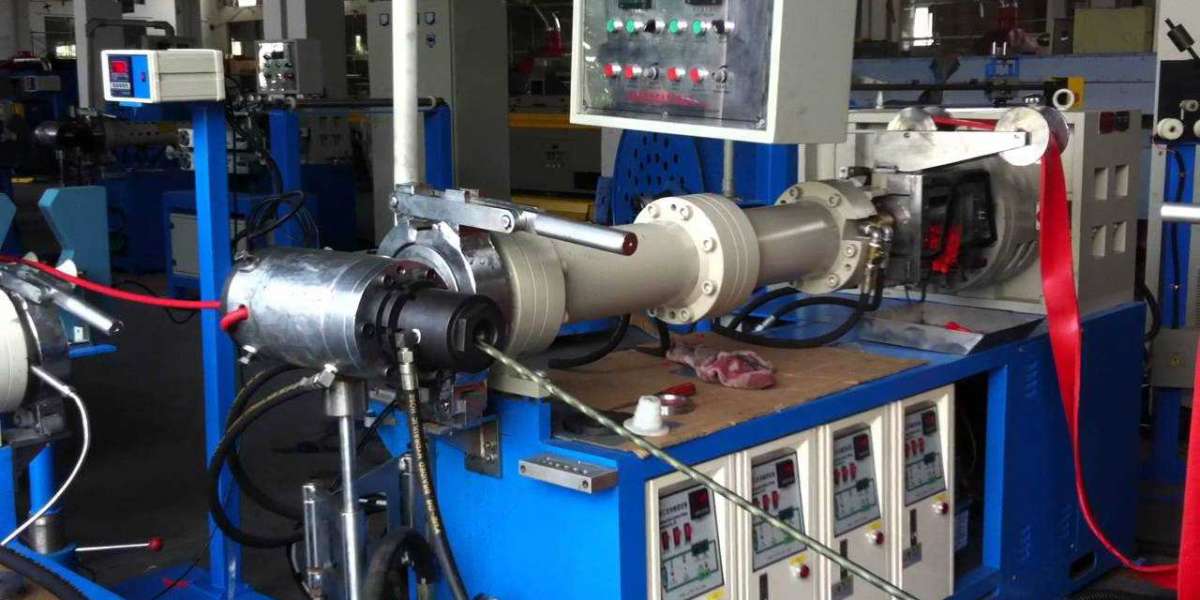

1. Feeding section

This stage of rubber extruder is also called the solid conveying section, which starts from the feed port until the rubber melts. After the rubber material enters the feed port, under the push of the rotating screw, the rubber material moves relatively between the spiral groove and the inner wall of the cylinder to form a micelle of a certain size.

2. compression section

is also called the plasticizing section, which starts from the melting of the rubber material until all the rubber material flows. The compression part receives the dough sent from the feeding part, compacts it, further softens it, and discharges air entrained in the chewing gum material to the feeding part.

3.Extrusion section

is also called the metering part, and the rubber material conveyed from the compression part is further pressurized and stirred. At this time, the rubber material in a completely flowing state has been formed in the thread groove. Due to the rotation of the screw, the rubber material flows from the flow channel with a certain volume and pressure and is uniformly extruded.